Phoenix blossoms, hot early summer. From May 8 to 12, 2023, the 5-day eighth UD391 and loader training class of LGMRT was successfully held. Service providers and customer representatives from all over the country gathered in factory of LGMRT to comprehensively and systematically learn the repair, maintenance, hydraulic and electrical knowledge of mining hydraulic boring trolley UD391 and underground shovel equipment, share resources and improve together.

In order to give full play to the important role of drilling equipment and underground shoveling equipment in the construction and production of cost reduction and efficiency, quality improvement and excellence, cultivate a group of high-quality skilled talents who are familiar with LGMRT’ products and "good communication, maintenance, operation, understanding construction and understanding principle", LGMRT accurately meet the needs of enterprises and users, around the pain points, difficulties and leakage points of equipment operation in special areas, Overall design of training courses including the integration of science and practice, as well as including the provision of teachers, site arrangements, including personalized training programs.

The training is divided into theory and practical training two agendas. LGMRT customized different training courses by the needs of different trainees, covering the whole machine hydraulic system, electrical system, water system and air compressor system principle training, Equipment maintenance and fault diagnosis training, rock drill, axle and other key parts of the disassembly, as well as four engine diagnosis, filter principle explanation, etc., to provide students with maximum value-added training services.

During the training process, the senior lecturers from Sandvik, senior service engineers of temporary mines, professionals from engine manufacturers and filter manufacturers will teach the experience and knowledge accumulated for many years to every detail in the construction link. From the classroom to the workshop to the whole machine storage area, the training team provided the students with a nutritious "knowledge meal" through the use of illustrated PPT, easy to understand teaching language and simulation operation demonstration.

After five days of full training, the R & D, quality, production and after market development departments of LGMRT and students together for batch discussions, humbly listen to the opinions of students and from the market "voice", and strive to customer demand-oriented, to provide partners with more reliable products and more accurate services. The students spoke enthusiastically and shared their training experience and future prospects. "The training course was well planned and arranged. Through the training, I systematically learned a lot of knowledge about the working principle, maintenance and other aspects of drilling platform and scraper, which laid a foundation for more standardized, safe and efficient use of machinery and equipment in the future!" A student sincerely said.

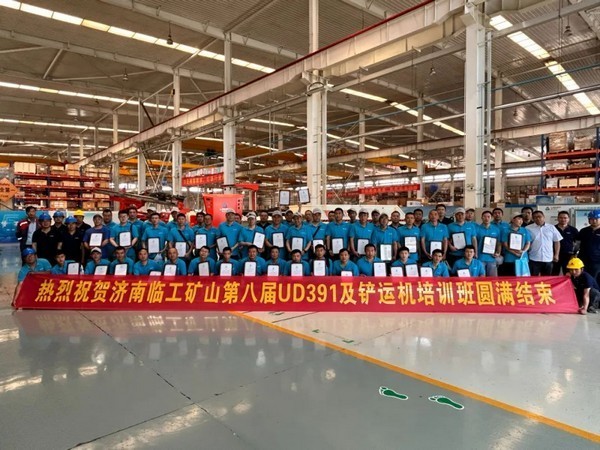

After a 5-day set of "intelligent, systematic, theory + practical operation as one" targeted training, combined with the theoretical examination results and training performance and practical results, LGMRT for the students issued a unified certificate of completion and outstanding students to commend.

Details determine success or failure. LGMRT always adhere to the intimate and patient service concept, customer-centric implementation of four good services, and continue to improve product quality and service capabilities. In the future, LGMRT will continue to serve the majority of mining machinery industry talents, jointly promote the training of professional mining machinery construction talents, and help the sustained, healthy and rapid development of the industry!